How to restore a classic sailboat

Restoring a classic sailboat can be a fulfilling and rewarding process, allowing you to create a personalized vessel for exploring the open sea with your family.

How to Restore a Classic Sailboat

Restoring a classic sailboat is a labor of love that can bring immense satisfaction and pride to those who embark on this journey. It’s a chance to breathe new life into a vessel that has seen better days, and to create a unique and personalized space for you and your family to enjoy the open sea. In this article, we’ll guide you through the process of restoring a classic sailboat, from finding the right boat to the final touches that make it truly your own.

Table of Contents

Finding the right sailboat, assessing the condition, creating a restoration plan, hull and deck repairs, interior restoration, rigging and sails, electrical and plumbing systems, engine and propulsion, final touches.

The first step in restoring a classic sailboat is finding the right boat. This can be a challenging process, as there are many factors to consider, such as the size, age, and condition of the boat, as well as your budget and personal preferences.

When searching for a sailboat, consider the following:

- Size : Think about how much space you and your family will need, both for living and storage. A larger boat may offer more comfort and amenities, but it will also require more work and expense to restore and maintain.

- Age : Older boats may have more character and history, but they may also require more extensive restoration work. Be prepared to invest more time and money into an older boat.

- Condition : Assess the overall condition of the boat, including the hull, deck, rigging, sails, and interior. A boat in poor condition may be a good candidate for restoration, but it will also require more work and expense.

- Budget : Determine your budget for both the purchase of the boat and the restoration process. Keep in mind that restoration costs can quickly add up, so it’s important to have a realistic understanding of what you can afford.

Once you’ve found a sailboat that meets your criteria, it’s time to assess its condition in more detail. This will help you determine the extent of the restoration work required and whether the project is feasible for your budget and skill level.

Consider hiring a marine surveyor to conduct a thorough inspection of the boat. They can provide valuable insights into the condition of the hull, deck, rigging, sails, and other components, as well as identify any potential safety issues or structural problems.

Take note of any areas that require immediate attention, such as leaks, cracks, or signs of rot. These issues should be addressed before any cosmetic work is done, as they can compromise the integrity of the boat and lead to more serious problems down the line.

With a clear understanding of the boat’s condition, you can now create a restoration plan. This should outline the work that needs to be done, the order in which it should be completed, and an estimated timeline and budget for the project.

Start by prioritizing the most critical repairs, such as fixing leaks or addressing structural issues. Then, move on to less urgent tasks, such as cosmetic improvements and upgrades.

Be realistic about your abilities and the amount of time you can dedicate to the project. Restoring a sailboat can be a time-consuming and labor-intensive process, so it’s important to have a clear understanding of what you’re getting into before you begin.

The hull and deck are the foundation of your sailboat, and any issues with these components should be addressed as soon as possible. Common problems include cracks, blisters, and signs of rot or corrosion.

To repair cracks or holes in the hull or deck, you’ll need to clean the area thoroughly, remove any damaged material, and fill the void with an appropriate filler or epoxy. Once the repair has cured, sand the area smooth and apply a protective coating, such as paint or gelcoat.

For more extensive repairs, such as replacing large sections of the hull or deck, it may be necessary to consult with a professional boatyard or shipwright. They can provide guidance on the best materials and techniques for your specific boat and ensure that the repairs are done correctly.

Restoring the interior of your sailboat can be a rewarding process, as it allows you to create a comfortable and personalized space for you and your family. Start by assessing the condition of the interior, including the cabinetry, upholstery, and flooring.

If the cabinetry is in good condition, you may be able to simply refinish or paint the surfaces to give them a fresh look. If the cabinets are damaged or outdated, consider replacing them with new, custom-built units that meet your needs and preferences.

Upholstery can be cleaned or replaced, depending on its condition and your personal taste. New cushions, curtains, and other soft furnishings can make a big difference in the overall appearance and comfort of the interior.

Flooring options for sailboats include marine-grade carpet, vinyl, or teak. Choose a material that is durable, easy to clean, and complements the overall aesthetic of the boat.

The rigging and sails are essential components of your sailboat, and their condition will have a significant impact on the boat’s performance and safety. Inspect the rigging for signs of wear or damage, such as frayed lines, corroded fittings, or bent or cracked hardware. Replace any components that are in poor condition or no longer meet safety standards.

Sails should be inspected for tears, fraying, or signs of UV damage. Small repairs can often be made with sail tape or by sewing, but larger issues may require professional repair or replacement. Consider upgrading to modern sail materials and designs for improved performance and durability.

The electrical and plumbing systems on a classic sailboat may require updating or replacement to meet modern standards and ensure safety and reliability. Inspect the wiring, switches, and electrical components for signs of wear or damage, and replace any outdated or faulty parts.

Plumbing systems should be checked for leaks, corrosion, or other issues. Replace any damaged hoses, fittings, or fixtures, and consider upgrading to modern materials and designs for improved performance and ease of maintenance.

The engine and propulsion system are critical to the performance and safety of your sailboat. Inspect the engine for signs of wear or damage, and perform any necessary maintenance or repairs. This may include changing the oil and filters, replacing belts or hoses, or overhauling the entire engine.

The propeller and shaft should also be inspected for signs of wear or damage, and any issues should be addressed promptly. Consider upgrading to a modern, efficient propulsion system for improved performance and fuel efficiency.

With the major restoration work complete, it’s time to add the final touches that make your sailboat truly your own. This may include installing new electronics and navigation equipment, adding custom artwork or graphics, or outfitting the boat with personalized accessories and gear.

Take the time to celebrate your hard work and enjoy the fruits of your labor. Your restored classic sailboat is now ready for new adventures and memories with your family.

Restoring a classic sailboat is a challenging but rewarding endeavor that can provide you and your family with a unique and personalized vessel for exploring the open sea. By carefully assessing the condition of the boat, creating a detailed restoration plan, and tackling the project one step at a time, you can breathe new life into a once-neglected boat and create a lasting legacy for future generations.

Sailboat restoration projects to get our boat ready for living aboard

Immediately after arriving in Washington from our delivery trip up the coast , we hauled out at a boat yard in Anacortes for the winter. We had a long list of sailboat restoration projects to tackle before we would be ready to move aboard that summer.

Undoing the damage from our delivery

REPAIR FORESTAY If you recall from our trip up the coast, our forestay and storm jib went crashing into the water during a storm as we rounded Cape Flaherty. Fortunately, the forestay isn’t crucial to support our free-standing mast, but it is crucial for running our headsail. We repaired the forestay using an industrial adhesive called Crestabond (it has now been over two-years, and our forestay is holding up perfectly!)

FIX LEAKS Over a decade of sitting in dry, sunny Southern California didn’t do any favors for our boat’s water-tightness. All porthole gaskets were dried out and cracking, and every hatch leaked around the acrylic. We replaced all gaskets and treated them with Vaseline to keep them hydrated. We then re-sealed all deck hatches around the acrylic.

REPAIR MAIN SAIL Since our mainsail tore from leech to luff as we left San Francisco, it needed a solid professional repair. Funny enough, as we were removing the sail and getting ready for our haul-out in Anacortes, we ran into a sailmaker from the Seattle area on the dock. He offered to take our sail then and there, and we were more than happy to hand it over. North Sails did a phenomenal job with our repair, extending the life of our tired, 30-year-old sail for at least another few seasons.

Getting rid of the stink

When we first went to look at our boat before making an offer to buy it, the biggest thing that stood out was the STINK. I’m talking plug your nose, can’t get used to it kind of smell. At the very top of our list of sailboat restoration projects before we could even think about moving aboard included eradicating the stink for good.

REPLACE HEADLINER The original headliner (ceiling) throughout the boat was made of thin wood panels wrapped in foam-backed vinyl. There was some visible discoloration, but once we removed a panel we realized nearly every inch behind the boards was moldy. We ripped out each panel, made templates, and installed new headliner throughout the boat using a plastic polywall material. No more mold for us! This was one of our bigger sailboat restoration projects that was challenging to DIY. Aside from a few YouTube how-to videos, there wasn’t much info out there for how to tackle this project without paying a professional to do the job. We learned a lot and would change a few things in retrospect. I’ll have to write more about this project in a future post!

REPLACE SANITATION HOSES/INSTALL COMPOSTING HEAD If you’ve spent some time around boats you’re probably well accustomed to the typical smell that comes with any boat head. Well this was on another level. It was clear the sanitation hoses in both heads had never been replaced, and the smell was now a permanent guest. Chris got the dirty job of removing all hoses, removing and cleaning the holding tanks, and reinstalling new hoses. We opted to only keep one traditional head and holding tank then replace our aft head with a composting system.

REMOVE HULL-SIDE CARPET AND PAINT STORAGE AREAS The insides of our large storage cubbies had a lining of old, dusty, musty carpet that had to go. We ripped out the carpet which was harboring all kinds of smells and opted for a fresh coat of paint instead. While we were at it, cleaned and repainted the insides of all large storage areas where we would stow food, household items, and sailing gear.

REFRESH CUSHIONS Most cushions throughout the boat also had some mold inside the foam. Getting brand new cushions and upholstery was well outside of our budget, so we opted for a deep clean. We removed and washed all fabric covers, then cleaned the foam cushions with a garden hose, tarp, and mold control products. I think some people are quick to think you need all new cushions on a boat every 10-years or so. If you have good quality cushions to begin with, you can really extend their life with cleaning and a bit of care.

Exterior sailboat restoration projects

INSTALL SOLAR PANELS AND WIND GENERATOR Having power while at anchor is much more sustainable when you can harness the power of the sun and wind. We installed two rigid 100 Watt Renogy solar panels on our stern pulpit and two 110 Watt flexible panels on our dodger. We also refurbished and installed a free wind generator that had a failed internal part. After some research, Chris ordered a relatively cheap part that he was able to solder and install inside the generator housing. It works perfectly!

INSTALL WIFI Having reliable WiFi on a boat takes a bit more effort than calling up an internet provider and plugging into the wall. The SeaBits blog by Steve Mitchell was particularly helpful for us when sorting out which system would work best for us. We ended up installing a MikroTik unit, which generally works great to amplify other WiFi channels and open hotspots for us to connect to.

REMOVE RADAR REFLECTOR FROM THE MAST The radar reflector on the mast above the forestay was a significant hazard each time we hoisted the main sail. The halyard would wrap around the unit and jam up, making it hard to hoist or drop the sail. We removed the large reflector and now have a smaller tube reflector installed on the stainless-steel mast at the stern.

PAINT THE BOTTOM Marine organisms and time did a number on the existing bottom paint, so it was time for a refresher. We taped off the water line, ground down the old paint, put barrier coat on the lead keel, and applied new anti-foulant bottom paint.

BUFF THE HULL AND INSTALL THE NEW NAME A little buff and shine goes a long way to liven up tired gel coat. Once the hull sparkled, we installed vinyl decals with the new name, Constellation , and hailing port.

Interior comforts

UPGRADE LIGHTS TO LED The original lights on the boat were old, inefficient, and dated. LED lights require very little power, will last virtually forever, and just plain look good.

CLEAN TANKS AND INSTALL WATER FILTER Our boat has a large water tank that we fill regularly and use for drinking, showering, and cooking. Before moving aboard, we treated the tanks with a bit of bleach, flushed them generously, and tested the water quality. We then installed a water filter at the galley faucet to make sure our drinking water was particularly fresh.

UPGRADE GALLEY AND SHOWER FIXTURES This was such a simple change that made a huge different for quality of life on board. Boats typically have small, utilitarian, “boat-y” faucets and shower set ups that just aren’t very luxurious. Swapping the old shower head and galley sink faucet was quick and easy but really helped modernize each space.

REPLACE MATTRESS The original mattress on the boat was just plain old and gross. The tricky thing with boat mattresses is they rarely fit a standard size. You have to either order a custom mattress or get creative. We got creative and cut our current foam mattress to shape using an electric turkey shaver and a bread knife. Hey, it worked!

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Books & Movies

- Cockpit Confessions

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← How-To DIY

Boat Restoration Projects

Advertisement

Three BoatUS Members share inspiring makeover stories of how they turned their boats from mundane to magnificent.

Cathern , 18-foot herman catboat.

For the last 35 years I've been building and restoring boats, initially as a professional but now, in later years, as an amateur. My projects range from building Hustler speedboats back in the 1990s to restoring theft- and storm-damaged boats. My dad got me interested in boatbuilding back in the 1970s when he bought a 20-foot Gil Smith catboat. The hours and days we spent together keeping that boat floating lit a spark that still burns within me.

Herman 18-foot Catboat before restoration.

Fast forward to 2013. I was feeling that something was missing in my life. Not wanting to get in over my head, I found a 12-foot Beetle catboat that needed some love. This got me back on the water, but it was just too small for Dad and me. I needed something larger.

Online searches brought up an interesting boat, an unfinished hull that was in need of a home and a friend: an 18-foot Herman catboat designed by Charles Whitzhull. She was scratch-built from plans supplied by the Wooden Boat Store. She is cold-molded with three layers of veneers sheathed with fiberglass cloth and epoxy. A guy in Kansas, who sadly passed away when the boat was only half complete, started the building of Cathern . After his passing, the hull sat for a while and the elements took their toll. While the hull was intact, the cockpit wasn't and required some serious rebuilding. I worked out a deal with the owner's widow and had the boat shipped east to my shop in New York.

Herman 18-foot Catboat after restoration.

Once in the workshop, I spent a year getting the boat ready for the water. I completely rebuilt the cockpit. There also was no interior to the cabin, so that was designed and constructed as well. I was able to source some secondhand spars from a boatyard that had a mast and boom almost the exact size needed. I'm a strong believer in recycling, so all of Cathern's deck hardware, except for her navigation lights, was recycled from damaged boats. Even her sail was a secondhand salvage. Cathern has proven to be a comfortable, family-friendly boat. It's been a great project and a craft that I think I'm going to hang on to for a while. Best of all, it's given me another reason to spend quality time with my dad.

— Ed Dankievitch, Port Jefferson, NY

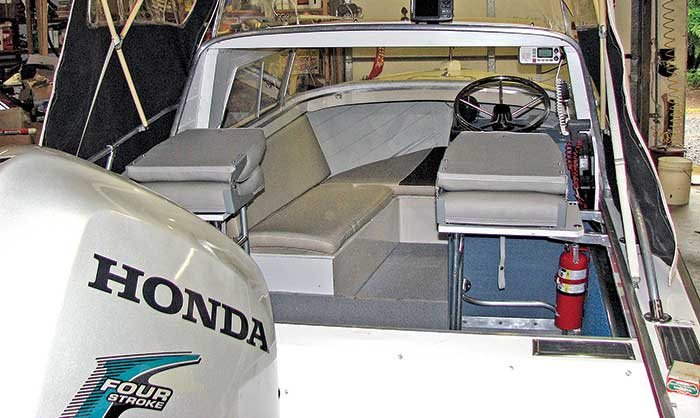

The Mary E , Starcraft Starchief

My aluminum Starchief was built and delivered in 1964 and, for the first few years, served as a family boat at a summer cottage on Indian River, Delaware. A few years later, we sold the cottage and brought the Starchief back to Virginia where it was used for a few fishing trips a year on the Potomac River and Lake Anna. Then, with other activities vying for my time, I put the boat in a machinery shed on my farm. The boat sat there for many years, though I looked at her often with good intentions of pulling her out, cleaning her up, and getting back on the water.

The Mary E Starcraft Starchief before restoration.

In 2008, in between work contracts, I transferred the boat onto a new trailer, as the original one had long since deteriorated. I had the 1965, 4-cylinder, 65-hp Mercury outboard motor surveyed; it was just too far gone from saltwater corrosion to be of use. I searched for more than a month for a period outboard, but in the end opted for a new Honda.

I had the hull sandblasted, and I painted the topsides with white two-part epoxy paint. This smartened up the boat considerably. It was during this work that we discovered some rot in the wood transom, which was addressed with epoxy resin. Thankfully, a localized repair was all that was required rather than a complete replacement. I stripped off the upper deck hardware, then stripped the paint from the deck. After some prep work, the deck was, like the hull, also painted with the two-part paint.

When I stripped out the interior, I found that the sole had some soft spots and needed replacing. Removing the existing sole, I found a whole new world of mice condominiums in the Styrofoam that dated back many years.

Trying to find marine plywood was a challenge. Sign shops became good sources for small scrap sizes, and they gave me leads on sources for 4-by-8 sheets. I used the old sole as a template for the replacement. Even disregarding the rot in the sole, I wanted to strengthen the replacement, so I used aluminum angles that I fitted in between the ends of the hull ribs. With these additional supports added, the sole felt very solid underfoot.

The Mary E Starcraft Starchief after restoration.

Finally, new marine vinyl flooring was laid on top of the plywood before reinstalling the reconditioned helm console. I decided not to put the port console back in to leave more open cabin access. Since the boat is more than 50 years old, I thought that she deserved a worthy name. I christened her after my mother, Mary Emily Dinterman Starkweather: The Mary E .

— Robert Starkweather, Cranes Creek, VA

Mike's Invader 21 Center-Console

Last April, we were faced with the possibility of our son, Tom, having cancer. It was the third time in his young 21-year-old life that he had heard that kind of news, but this time the prognosis was different and more troubling. I thought, if we're battling cancer, we're going to need a distraction. So what better than a little boat renovation that we could work on together to take our minds off all the scary stuff?

Invader 21 center-console before restoration.

It just so happened that my neighbor had a boat that had been sitting unmoved in his driveway since 1991, a 1986 Invader 21-foot center-console with a 150-hp Mercury outboard. I bought the boat thinking that I just needed to replace the sole and would have the boat on the water in a few weeks. How wrong I was! It was only after removing the tuna tower and sole that I saw the extent of damage. Years of water sitting in the boat had disastrous consequences on the structure. I ended up removing all the stringers, foam, and bulkheads until only the outer hull shell remained. I had a 21-foot canoe sitting on my driveway!

Little by little I rebuilt all those components and refiberglassed everything into the hull, followed by a repaint. More than a year from my initial start date, I had a completely rebuilt boat replete with new motor.

Invader 21 center-console after restoration.

This story has two happy endings. Not only do we now have a boat, but it also turned out that my son didn't have cancer. We got to enjoy some father-and-son bonding time while we worked on the boat, so that was a win-win. Since we've had the boat, which we have yet to name, we've enjoyed day trips out to Catalina Island, and we recently towed it to Lake Havasu in Arizona for an inland boating experience.

— Mike Walters, Chino Hills, CA

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

Contributing Editor, BoatUS Magazine

A marine surveyor and holder of RYA Yachtmaster Ocean certification, BoatUS Magazine contributing editor Mark Corke is one of our DIY gurus, creating easy-to-follow how-to articles and videos. Mark has built five boats himself (both power and sail), has been an experienced editor at several top boating magazines (including former associate editor of BoatUS Magazine), worked for the BBC, written four DIY books, skippered two round-the-world yachts, and holds the Guinness World Record for the fastest there-and-back crossing of the English Channel — in a kayak! He and his wife have a Grand Banks 32.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

You are using an outdated browser. Please upgrade your browser or activate Google Chrome Frame to improve your experience.

How to Restore a Boat (And What to Consider)

Boat owners often form deep bonds with their vessels, motivating them to restore rather than replace them. This commitment to preservation allows us to appreciate the enduring beauty of classic and antique boats. Plus, it's a budget-friendly option compared to purchasing new.

But before diving into boat refurbishing, it's essential to understand that restoring a boat requires considerable time, effort, and resources. This blog post will explain how to restore a boat, the pros and cons, and restoration alternatives.

The Pros of Restoring Your Boat

Let's discuss why people choose to restore their boats:

1. Cost Compared to Buying New

Aside from sentimental value, many people opt for restoration because it's cost-effective compared to purchasing a new boat . While material expenses can accumulate, they don't compare to the hefty price tags of brand-new boats. Restoration expenses primarily involve the cost of supplies and occasional assistance from a laborer for more challenging tasks.

2. Sense of Accomplishment and Pride

Building and restoring your boat creates a unique masterpiece tailored to your style and preferences. Your one-of-a-kind creation will be a testament to your dedication and craftsmanship – a vessel built with your own two hands.

3. Develop New Skills or Improve Old Ones

Every restoration project is an opportunity to learn valuable boat skills! Throughout your journey, you'll gain practical knowledge about mechanics, parts, and additional information needed to complete your project.

The Cons of Boat Restoration

Restoration projects can be demanding, and many sailors are hesitant to commit. Several factors influence people's decision not to undertake these types of projects:

1. Time and Effort

Restoring a boat can be seriously labor-intensive! Restorations require a significant time commitment, as you must allocate several hours. Many people find long-term restorations peaceful and satisfying. However, others find the pressure to complete it before the season begins overwhelming.

2. Unknown Challenges

You'll inevitably encounter unforeseen challenges. For instance, depending on your boat's make, model, and year, the manufacturer might not even sell that part anymore – meaning you'll have to get creative. If you expect the unexpected, you'll overcome any challenges!

3. Liability Concerns

In the unfortunate event of an injury, you'll likely bear responsibility for any resulting damages. Additionally, note that the quality of your craft can impact your boat's warranty and cause potential insurance complications. For this reason, it's best to hire a professional if you're unsure how to restore boat parts.

How to Restore Boat Accessories and Parts

Before you begin restoring, it's essential to have your vessel surveyed by a professional. This helps uncover hidden problems lurking beneath the surface (pun intended). In addition, doing so saves you time, money, and headaches.

Next, make sure to clean every nook and cranny. This step might seem counterintuitive but will benefit you in the long run. Cleaning removes obstructions and makes inspection easier. You should also remove any unnecessary hardware and finishes.

Now it's time to carefully plan your restoration, making a list of materials you need and the order in which you'll tackle tasks. Once you're ready to begin, start with essential structural repairs like fixing holes, leaks, or rot. This includes inspecting, repairing, or replacing weakened parts.

The next step is to repair all lines and sails . Then, decide whether engine repairs or replacements are the way to go. Once you restore the major components, it's time to sand, seal, add finishes, and replace hardware. Then, you can address interior elements like floors and seats.

Finally, test everything on both land and water to ensure it functions as it should. We also recommend creating a maintenance plan to ensure your hard work stays at its best.

Additional Tips for Boat Restoration

If you're up for a rewarding restoration project, consider checking out repossessed boats available for purchase online or at boat lots. These are significantly more affordable than their new or used counterparts. Additional alternatives to boat restoration include buying a used vessel or hiring a crew to restore a boat.

Here's another money-saving tip: Consider purchasing upcycled or repurposed parts instead of brand-new ones. Not only will you save money, but you'll be breathing new life into old pieces.

Lastly, you'll want to document your progress with photos and notes and test everything you do. This helps you keep track of your work and ensures you have proper insurance company documentation.

Wrapping Up Boat Restoration Advice

Refurbishing a boat can be a rewarding and uniquely challenging experience. And trust us when we say there's no greater satisfaction than seeing your vision come to life. If you are considering boat restoration, we hope this article points you in the right direction! Good luck, captain.

Join Our Newsletter!

Get community news, buying bargains, and how-to guides at your fingertips.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Catalina 270 vs. The Beneteau First 265 Used Boat Match-Up

Ericson 41 Used Boat Review

Mason 33 Used Boat Review

Beneteau 311, Catalina 310 and Hunter 326 Used Boat Comparison

Tips From A First “Sail” on the ICW

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Thinking Through a Solar Power Installation

Polyester vs. Nylon Rode

Getting the Most Out of Older Sails

How (Not) to Tie Your Boat to a Dock

Stopping Mainsheet Twist

Fuel Lift Pump: Easy DIY Diesel Fuel System Diagnostic and Repair

Ensuring Safe Shorepower

Sinking? Check Your Stuffing Box

The Rain Catcher’s Guide

What Do You Do With Old Fiberglass Boats?

Boat Repairs for the Technically Illiterate

Boat Maintenance for the Technically Illiterate: Part 1

Whats the Best Way to Restore Clear Plastic Windows?

Giving Bugs the Big Goodbye

Galley Gadgets for the Cruising Sailor

Those Extras you Don’t Need But Love to Have

What’s the Best Sunscreen?

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

How to Select Crew for a Passage or Delivery

R. Tucker Thompson Tall Ship Youth Voyage

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

On Watch: America’s Cup

On Watch: All Eyes on Europe Sail Racing

Dear Readers

- Boat Maintenance

Rebuilding a Cape Dory 36

T his is Part 1 in a multi-part series detailing the rebuilding of our then 35 year old Cape Dory 36 sailboat. The purpose of this series is not to provide step-by-step instructions, but rather provide useful insights and general knowledge should the reader want to undertake a similar project.

My choices and methodology reflect my experience, philosophy, and vision. While there is more than one way to accomplish such an extensive project, our approach worked well for us and the result exceeded our expectations. I had no previous boat building or woodworking experience. While it is undeniably true most boat rebuilds are not successfully completed, there are steps you can take to put the odds in your favor. Part I describes what might be called “best practices” to ensure the rebuild has the highest chance for a successful outcome. It covers important topics that framed our project from beginning to end.

Let’s address up-front the biggest criticisms I hear from the naysayers about boat rebuilds. “It will take you longer than you think; it’s cheaper to buy a boat ready to go than rebuild one; and my favorite—you will fail because it’s harder than you think and your boat will be relegated to the boatyard of broken dreams.” All three statements are true…for “some people.” My observation is those who vociferously oppose the idea failed in their own attempt. But, for me, and many others, a rebuild was the only affordable way to get the boat I wanted. Starting with the right boat, establishing a budget you can afford, showing restraint in outfitting her, and remaining committed to the end will get you across the finish line.

REBUILD VS REFIT

I define a refit as actions taken to repair a boat and make her ready to go to sea again. New standing and running rigging, new sails, paint, system upgrades and repairs to machinery to include a new engine comprise the projects normally associated with a refit. I define a rebuild as more extensive and invasive as it will include major projects to reconstruct a boat from a degraded condition to a “like-new” condition. It will likely include everything described in the refit but probably include major structural projects that require gutting the boat in part or in total.

A life-long sailor, I have owed the Far Reach , a Cape Dory 36 (Hull #61), since 2001. In April 2009 I gutted her to a bare hull. Only the hull, deck, rudder, hatches, cleats, a few bulkheads, and ports from the original boat were retained. Every piece of hardware, wood, and fastener was removed from the boat. We made major design changes and numerous modifications to the interior and exterior. She also got a new, lighter, taller rig. This was a major rebuild. She emerged from the rebuild in May 2015 a new boat. She is a stronger, faster, more capable boat than when first launched in 1982. Since her relaunch I have sailed her 11,000 nm, mostly offshore, mostly singlehanded. She has safely carried me from NC to the Virgin Islands and back three times.

One of the things I have learned in sailing (and in a lifetime of military operations) is that complexity creates friction. Friction can make the easy difficult, and the difficult impossible. The more complicated systems and plans are, the more likely there are to be problems and the more extensive the knowledge and resources required to fix them. The older I get the less tolerant I am of needlessly complex and fussy systems which detract from the beauty of the simple voyaging experience I crave.

While I envisioned my voyaging boat to be sailing centric, I was determined she would also be simple enough that I could fix anything that needed repairing. I also desired there to be as few barriers as possible between me and the physical sailing environment I enjoy. I wanted “my wits” to be at the center of my decision-making, vice technology. I wanted to be sailing with my head “outside” the boat looking at the water, the sails, the wind and not “inside” the boat looking at instruments. I wanted adventure, not convenience. What is the satisfaction in sailing a boat that does everything for you?

Along with simplicity, I wanted the boat to be elegant with a comfortable and inviting interior I would enjoy being in for long periods of time. There is no right or wrong way to enjoy sailing but that is the vision that guided all our decisions.

An important part of the vision was a strong and reasonably fast boat. She had to be watertight. No wet clothing, charts, books. No mildew from water leaks. No ruined electronics. She needed to have lots of storage and be tough enough that I could sail wherever I wanted without worrying about her not being up to the task even if I was not. The boat had to be easy to handle for one or two people.

After looking at all kinds of boats I ultimately chose a down-on-her-luck 20-year-old CD 36 because I liked her looks, she was designed by a legendary architect (Carl Alberg), and did not have a liner which made planned interior modifications less complicated. She was of conservative design with attached rudder and a solid fiberglass hull. She had a reputation for being well behaved under sail. She was in the displacement range (16,100 lbs) that could accommodate a small family or a couple for voyaging. And I could afford her.

I created a rebuild budget based off my best estimate that supported the vision. My time and labor I viewed as zero otherwise you’re kidding yourself. I could afford my labor—I couldn’t afford someone else’s labor. I avoided the temptation to hire professionals to accelerate the rebuild with two exceptions—I paid $600 to have the topside sprayed and $1,500 for upholstery. By keeping the boat simple, with few systems, most of the money went into wood, fiberglass, epoxy, and fasteners. I sold most of the components and equipment I removed from the boat. All that money went back into the boat fund. I stayed close to the budget until the very end then added about $10K to purchase new sails which was the result of an unforeseen opportunity to get a new taller mast at a huge discount. More on that later.

I had practically no building skills when I started this project. To prepare myself I joined a woodworking fellowship. One night a week for eight months I joined a group of men at a woodshop and they guided me as I built a kitchen workstation from scratch. They taught me how to measure, mark, and cut wood. I learned how to plane and joint wood and how to glue and clamp. I learned how to use tools safely. Opportunities like this exist in nearly every community. You just have to look for them. Everything else I learned as I went.

When people ask me the secret to rebuilding a boat, I say it’s not the budget or the lack of skill or a shed that will keep you from success. It is a lack of commitment. You will face a thousand obstacles. You need the determination of a junkyard dog. You need a vision and a ruthless determination to feed it from start to finish. I documented the rebuild on a website for two reasons. First, to give back to the community so others could benefit from my efforts. And, second, to remind myself of the progress I had made when the going got tough and it felt like I would never get to the end. One of the advantages I had was I am a life-long sailor. I started sailing as a pre-teen, have owned and raced sailboats for many years, and I lived on a boat and sailed in the Bahamas as a kid. So, I knew deep down inside what I was working towards. I knew why I wanted a simple, seaworthy, elegant, and reasonably fast sailboat. So, for me, I never thought for a moment I would not complete the project. What I did not know, however, is how long it would take, how difficult it would be, or how it would turn out.

I have an extensive sailing library that shaped my philosophy of sailing which is heavy on simplicity and skill and less on technology and complexity. My books mostly cover the golden age of voyaging—1900s to 1990—before the widespread use of SatNav/GPS and “convenience” systems. I relied on books like Skene’s Elements of Yacht Design, Chappelle’s books on yacht construction, books by Eric Hiscock, Hal Roth, Don Street, the Pardeys, Harry Pidgeon, Vito Dumas, John Guzwell, H.W. Tilman, the Smeetons etc.

I also have books on metallurgy and wood and fiberglass construction principles to expand my knowledge in related disciplines. I seldom get important information from the internet. I rely on books and the experience of sailors I admire to inform me and I turned to them often for advice and insights as I made my way forward.

There are common themes in these books—boat strength, self-reliance, and simplicity. I think you get into trouble when you randomly mix philosophies. If you are all about a simple strong boat you can maintain yourself, then incorporate leading edge technology and complex electronics, mechanical systems, and exotic materials, your boat gets out of synch with your vision (and perhaps your skills) not to mention it drives up the cost.

During my voyages I have met many boat owners trying to cruise on a finite budget but were exasperated trying to find parts and qualified technicians to repair equipment too complicated for the owners to repair themselves. Every piece of equipment on a boat, be it mechanical or electronic, will be tested to the max when ocean sailing and voyaging to remote destinations. Most will fail or give you trouble at some point.

If it’s simple, it’s less likely to fail, and if it does you can fix it yourself. But, if you want convenience, comfort, and technology you will be unhappy with a simple sailing-centric philosophy. So, it’s important you know what you want when you start a rebuild, develop a realistic budget, then stay on track to achieve it—simple, complicated, or somewhere in between. Because my boat is very simple, it cost me far less to rebuild and maintain.

A mentor is more than an expert. He or she is an experienced advisor you trust and respect to guide you through a project. A mentor is inspired by your dedication to the task and your ability to be taught. I had two mentors. One is an expert restorer of classic fiberglass boats (Tim Lackey, lackeysailing.com). He has an incredible range of skills and a pragmatic philosophy that kept me on track and was amazingly supportive. I could not have had a better teacher and advisor. The other is a certified Swedish furniture builder (Kaj Jacobson, knjwoodworking.blogspot.com), a craftsman with jaw dropping woodworking skills who built his own boat (FC 34) from a bare hull into a piece of art.

Neither of these men have physically seen my boat but their fingerprints are all over it. They were instrumental in guiding me during the rebuild. They invested a lot of time helping me understand what I needed to do to achieve my vision even if it was not their vision. The fact they are sailors and appreciate the benefits of an uncomplicated boat was helpful.

Mentors, like books, need to be philosophically aligned with your vision. If not, then they are not the right mentors. However you do it, you need to develop a relationship with a competent mentor. I can count the number of times on one hand where I did not follow the recommendations of my mentors and each time it proved to be a mistake. If you ignore the advice of mentors they will tire of the investment in time they make supporting you, and leave you to carry on without them. So, choose them wisely and then listen to them.

Big projects like a boat rebuild will be exhausting in terms of time, energy, money. If I were ever to write a book on rebuilding a boat, I would devote a whole chapter to this one subject. The ability to maintain your sanity and sense of humor through the project is essential. I had more than one temper tantrum and several times I got so frustrated I had to lay my tools down and walk-it-off to clear my mind.

I once commented to a friend how excited he must be to have his own rebuilt Hess 30 finally sailing and he said to me, “To be truthful I am too exhausted to enjoy it right now.” Well, that turned out to be exactly how I felt when we finally splashed the Far Reach after six years. I was just numb from the degree of mental and physical effort it took to complete such an enormous project alone. I then understood why so many people give up—it feels at times like it will never end and for many people eventually the vision dims to a pin prick then disappears altogether. With the boat in the water I pressed ahead without a break completing additional projects to prepare our boat for our first 1,600 nm offshore voyage. By the time we took our departure from Cape Lookout, six months after we launched her, I was completely mentally exhausted driven only by the singular focus to sail to the West Indies.

There are things you can do to put the odds in your favor of a successful rebuild. The shed I describe on page 13 is one of them. Accept it will take longer than you think. Work on the boat every day—even if only a half hour so you don’t lose momentum. You have to make time for boat work. I was recently retired but I taught homeschool from 0800-1200 five days a week. I typically worked on the boat from 1300- 1800 every day. Longer on the weekends.

It can be done and I know a lot of people that have completed big projects using this strategy—“eating the elephant a bite at a time.” That is why having the boat at your home is so important. You have to be ruthless about protecting your time. Time is not recyclable. Every five minutes you spend on social media is five minutes you won’t have to work on the boat. It’s five more minutes you have to add to the length of time required to finish the rebuild and launch the boat.

It’s a battle of inches, not miles. No one should believe a boat rebuild is going to be easy. I estimate I spent 6,000 hours on the rebuild of which probably half was spent reading, thinking, planning, drawing, researching, and ordering supplies. That comes out to about 3 hours a day plus 8 hours over an entire weekend for 50 weeks a year, for six years. A simpler rebuild might have taken 3,000 hours or less. An experienced builder could do it faster. Most rebuilds will not be as extensive as mine.

Often overlooked is the significant time put into planning. I drew out and diagramed every project from interior layout to joinery. In the evenings I looked at websites of classic boats to get joinery ideas. Usually, I worked several projects simultaneously. Varnish was drying on one project while I was fabricating or milling wood for another. To keep the momentum going I learned to plan several projects ahead so I could order items and have them on-hand for a seamless transition from one project to another. Loss of a momentum between projects is a killer, but you can reduce this lost time by having the next project spooled up and ready to go as soon as the current one is complete.

You need to be clear in your own mind what your rebuild priorities are. Mine were sailing performance, strength, simplicity, self-sufficiency, comfort and convenience, in that order. Safety is not on the list. Safety is inherent in the first four categories and is more about what’s between your ears and less about what’s bolted to the boat. I had to make some hard choices when it became apparent some ideas would not work. But I stayed true to the vision and made changes that aligned with my priorities. It all worked out.

A large part of my rebuild was wood centric and most of my tools reflect that focus. None of my tools are “high end.” I have a table saw; a modest dado blade set; an inexpensive jointer and planer; a good jig saw; a modest chop saw; a hand-me-down bench top drill press; a couple battery powered drills; a desk top belt sander and a small bench top router table; an inexpensive dust collector; some hand planes, spoke shave, and draw knife; a couple cabinet maker’s files; a wide range of drill bits, an RO sander, a shop vac, etc. Nothing fancy.

I lusted for a band saw. I did not have room. I gained access to one when I needed it. Depending on your boat and your vision you might have less wood work in your project than mine. Unless you are rebuilding a wood boat you will probably not have more. I estimate I spent about $2,500 in tools acquired over time. But tools like your skills are an investment and you will use them for all kinds of other projects.

From beginning to end a rebuild is a major undertaking. A thoughtful, realistic, holistic plan will help you complete it. With the background out of the way, next month we will dive into the project.

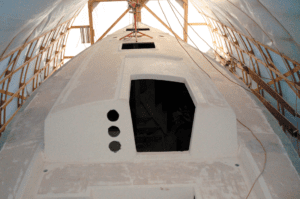

T he single most important step I took to completing the rebuild was locating the boat in a shed at my suburban home. W e got approval from our HOA and I obtained a building permit from the town for the temporary shed. The ability to be able work on the boat after working a day job is a huge advantage. My commute to and from the boat was 70 feet vs. 70 miles.

Having the boat at home kept me engaged with my family during a multi-year project. I was able to take care of home projects which did not go away while I was working on the boat and reduced the likelihood my family would come to resent the boat. Since I was home, I was available. I could stop a project any time and leave the tools on the boat and they were ready the next day. I did not lose valuable time or incur the expense of traveling to and from a boatyard. There were no monthly storage fees draining our budget.

I built a Stimpson Bow Roof Shed from a set of plans that cost $20. It was uncomplicated and within my modest skills, at the time. The total cost of the project was about $1,200. The eye of Hurricane Irene made landfall in NC in Aug 2011 about 30 miles away. Windspeed in our town was clocked at 100 mph. You can see a video of the shed during the storm online (see https://youtu.be/MAX5iEg2oQ0 ). When I completed the project, I sold the bow frames for $500.

1. It took a month and $1,200 to build the Stimpson Bow Roof Shed ( www.bow-roof-shed.com ). The shed allowed me to keep working regardless the weather. The strength was impressive, surviving hurricanes, snowstorms, and heavy downpours.

2. I put together a small workshop with modest tools. In this photo you can see the chop-saw to the left, table saw behind it, and a small bench top belt sander. To the right you can see an inexpensive dust collector. The hose is long enough to reach all the tools. Under the workbench to the right you can see a bench-top router table and a two-speed thickness planer. The drawers hold hand tools. My neighbors were very supportive. My wife joined the home owner’s association committee to head any issues off that arose. None did, although after a couple of days of non stop sanding one neighbor did confront me asking “Will this noise ever cease?” I got her to laugh by replying, “No. Never.”

We gutted the original interior to improve storage and ensure the Far Reach was safe and practical offshore and comfortable to live aboard at anchor.

1. September 2010. The original interior was gutted to a bare hull keeping only a few structural bulkheads in place. I cut out and removed the one-piece fiberglass overhead liner because I wanted complete access to the underside of the deck.

Also, I did not want to see any fiberglass inside the boat taking away from the traditional aesthetic we desired. The floor timbers and sole were also removed to make way for water tanks and storage.

2. March 2015. We designed and installed the new interior (covered in Part II) pulling it toward the centerline creating more storage space outboard and under the furniture. We added pilot berths with lee cloths for safe comfortable sleeping offshore while keeping the settees and saloon table open for use. We eliminated the ubiquitous V berth in the forward cabin preferring a more companionable double berth we use when not underway. The saloon stanchions support a fold-over varnished ash table I built after we launched the boat. The boat is easy and safe to move through even in rough offshore conditions as there is always solid furniture and the saloon stanchions to grab. The storage space is huge for a 28’ waterline.

To keep the visual aesthetic grounded we worked from light overhead to a dark sole. In between, the vertical surfaces are V groove African Mahogany with seven coats of high gloss varnish which reflect light and create a sense of more space. The horizontal surfaces are varnished ash. The raised panel inset cabinet doors are varnished bird’s eye maple.

I I put a lot of thought—and a whole lot of work into the deck. I was determined to have a dry boat.

1. January 2010. I removed every fastener and filled more than 300 holes. No wonder sailboats leak.

In this photo I had ground the gunwale down in preparation for glassing over the hull deck joint with three layers of 1708 biaxial and West Systems epoxy. The original nonskid has been sanded off.

Later I glassed in the instrument holes on the aft end of the cockpit and the engine control panel in the cockpit footwell plus many other major holes. Since we eliminated the inboard engine we filled in exhaust and bilge pump holes in the transom and the propeller aperture in the keel.

When all the glass work was completed we rolled on four coats of Awl-Quick epoxy primer. The topsides, cabin top, and cockpit were painted with Awlgrip. I applied Kiwi-grip for non-skid.

2. March 2015. The morning after we disassembled the shed, and my first view of the Far Reach in her entirety. It was a thrilling moment after so much hard work. She was not only a new boat, but a stronger, safer, faster boat.

The storage space was vastly improved. She was dramatically simplified. The 6 ¾-inch tall raised bulwarks allow water to instantly drain over the side and significantly improves safety for the crew offshore.

You can’t appreciate how much safer and more reassuring bulwarks are until you go forward at night offshore in ugly weather. On each of our offshore voyages we arrived at our destination with a totally dry bilge.

In this photo the Cape Horn windvane is prominent. It has proven itself to be the most valuable member of the crew on every voyage we have made.

RELATED ARTICLES MORE FROM AUTHOR

Mastering Precision Drilling: How to Use Drill Guides

15 comments.

Loved your article… after reading it, it brings back fond memories of my two loves, my 1982 Cape Dory Typhoon “Windsong”, and my 1984 Cape Dory 25D “Feather” recently sold and miss, as my 82 years have caught up to me health wise, and I’m left with great appreciation for the truly fine design and strong build of the Cape Dory line. My question was, what did you repower your vessel with?

Bob, I am glad you enjoyed the article. The Typhoon and 25D remain the most sought after boats in the Cape Dory line. Both are lovely capable boats.

I sailed the Far Reach without an inboard engine for five years including two round trips from NC to the Virgin Islands. I relied on a 14’10” ash sculling oar as my primary means of non sailing propulsion when practicable. It works surprisingly well if set up properly.

I also had a custom built swing arm bracket I could bolt to the boat. I used it to hold a Honda 9.8 HP outboard when we needed to move the boat down narrow canals or in restricted water when the conditions exceeded the capabilities of the oar. The little outboard would move the boat at 5 kts at 3/4 throttle on flat water. I demonstrate how the outboard bracket works on our YouTube channel, Far Reach Voyages. In 2021 I installed a small diesel with a two blade folding prop which is the subject of a future article in Practical Sailor.

Wery nicely spelled out what it takes to fulfil ones dream. Yes I sord of missed that part , like Bob Nelson . You didn’t use oars “”””

Helmet, Thanks. I answered your question in my reply to Bob Nelson.

I have broken way more tillers than wheels on boats. Plus easy to lock down the rudder with wheel steering, not so much with a tiller. When Andy made the CD line, he said he regretted not stiffening up the deck supports. Did you address that issue?

Robert, Your experience is different than mine. I have never heard the argument a wheel is more reliable than a properly built tiller. The strengthening of the hull and deck are addressed in Part 2.

Totally agree with your philosophy of keeping things simple. If your head is out of the boat then you don’t need expensive power consuming, high maintenance instruments to know where the wind is coming from. Have you repowered and how? Tillermate, a locking tiller mechanism from Canada is the best I have used – never broken a tiller yet!

Kate, regarding repower see my reply to Bob Nelson. Thanks for the comment on the tiller lock. I have looked into them (Practical Sailor ran a test on them a while back) but I have been reluctant so far to bolt anything to the tiller to snag lines. I usually tie a short length of line around the tiller with a clove hitch and lead the ends to cleats on the coamings. However, I seldom sail without the self-steering windvane which negates the need for a tiller lock when engaged. Still, a tiller lock seems very useful.

Sound advice. Looking forward to the part 2 Rebuilding my Pearson Triton 28 Misty. 1965 Interesting that I pretty much came up with the same conclusion as to my rebuild as you. Took a woodworking class , read the old ” books” and new books. Planned about 3 project ahead so when the epoxy was drying (every piece of wood coated with 3 coats) then varnished, started making patterns and cutting wood. Rewired and plumbed everything. Made a project book one page for the planning and opposing page for supplies and tools needed so when I had to drive to the boat I would not forget at home what I needed 45 minute drive. Project book kept me on tract. It takes lots of time I’m in to it for about 5 years. I see the light at the end of the tunnel nw had to take breaks along the way. I work on the boat everyday! Thanks for you sharing of your experience.

Thanks. Good luck with your rebuild. Hang in there!

A great read. Thanks for the effort.

Thanks. I enjoyed writing the series.

Personally, I use oil based sign paint on my boat and though it doesn’t hold a shine long, it’s relatively easy to use and easy to redo. I haven’t found the two part to be more resistant to anything but the sun and to mildew. I like pumice for nonskid—inexpensive. I also haven’t found the two part more resistant to scratches and chipping. Anyone reading this agree?

Susan You did not mention what kind of surface you are painting, or under what conditions.

I use a one part LPU paint, like Interlux Brightside on exterior wood and have had excellent result. That’s where I would use and oil based or alkyd based paint.

A two part urethane paint (like Awlgrip) is not normally a good choice for wood because the paint does not give when the wood expands and contracts with changing temps and humidity. The paint will crack.

Both kinds of paints require similar preparation but the two part typically last twice as long on fiberglass. There is a C&C 39 in the boatyard near the Far Reach. It was Awlgripped 17 years ago with flag blue. It still looks pretty good.

But if a one part alkyd paint meets your needs then perhaps that is the best choice for your specific situation.

Totally agree with your philosophy of keeping things simple and your head outside the boat. My Cal 2-29 doesn’t even have a depth sounder; her only “instruments” are a compass, some telltales on the sails and a wind vane on the masthead. Well, ok, sometimes I’ll pull out the GPS on my phone to see how fast I’m going but that’s about it.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

Hans Christian 41T – Boat Review

Seven dead after superyacht sinks off Sicily. Was the crew at...

What’s the Best Sailboats for Beginners?

Why Does A Sailboat Keel Fall Off?

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

12 Tips For Restoring an Old Boat: Costs, Time, And Expert Advice

Looking at restoring an old boat chris mccall shares his expert advice..

So, you’re thinking of buying an old boat and bringing her back to her former glory? Awesome! Get ready for hard work and frustration culminating in an ultra-rewarding experience.

Buying and refitting an old sailboat is totally worth it! You won’t build a ton of equity in the boat, but you will know every square inch of that vessel, and the skills you gain will be invaluable.

My wife and I just finished the three-year refit of our 1972 Nauticat 38, Drifter, and now live aboard in Portland Oregon. As soon as the weather cooperates, we plan to take him (Yep, Drifter’s a fella) south and begin cruising full-time.

Feel free to check out our progress along the way and the results of our labor; you can find us on YouTube at YouTube.com/SailingAdrift

As an Amazon Associate, we earn from qualifying purchases. We also earn from other affiliate programs. This means we may receive a small commission on products purchased through our links at no extra cost to you.

Here are my top tips to help with your refit. Most I followed; some I wish I would have.

During The Buying Process

Get one of the best knives for sailing

Before you buy your perfect renovation project boat, here are a few tips to follow so you don’t fall short at the first hurdle.

#1 Know what you’re getting into

Refitting a boat is not an easy undertaking, and the single biggest thing keeping you from success is your tenacity to see it through. There are so many boats for sale, half-finished, because the undertaking was a lot more than their owners predicted. So….

#2 Plan, Plan, Plan.

This post is a great place to start. Start taking notes and tour as many boats as you can to gather ideas.

Talk to people that know. Read books. Read articles. Watch YouTube refit videos. Join social media groups focusing on refits, interior design, electrical systems, electronics, and boat makes you’re interested in.

I know the excitement is high but take a beat and make sure you make a logic driven decision based on research. There will be time to fall in love later.

#3 Make a core list of what you want from restoring an old boat

List the makes, lengths, characteristics, and price range and stick to it.

Then make a list of “nice to haves” and look for boats that have as many as you can find. If you go in with a clear understanding of what you want, and the deal breakers associated, it’s much easier to make a smart decision.

#4 Let someone else take the depreciation if you can

If you’re going to be refitting, you’ll be taking on plenty of depreciation as soon as you start installing your new electronics, appliances, and equipment, so minimize it by finding a boat where the previous owner has installed as much of this stuff as possible.

New engine? Awesome! Just upgraded all the navigation equipment? Great. New refrigeration unit? That helps. Let the last guy take the hit for 50 cents on the dollar.

Wondering how much sailboats cost ? Get a rough idea here.

#5 Buy cheap and pay cash if you can

Boats are not like houses. There isn’t nearly as much competition for boats that need a fair bit of work, because you won’t build a bunch of equity refitting like you would flipping a home.

Don’t expect to save tons of money refitting the boat yourself. You may save yourself a little but the real value is in the knowledge of the vessel and the skills you’ll gain.

So be ready to offer significantly less than asking, and don’t be surprised if they take it.

#6 Include a survey contingency and evaluate your prospective project from top to bottom

Do you have to hire a surveyor? No. But if you don’t, get ready to learn all you can about the process, and go over every square inch.

Know someone super knowledgeable you can ask to help? DO IT! Do not be afraid to walk away. Getting attached leads to bad decisions.

Now That You’ve Got Your Boat Restoration Project

So you’ve found your dream boat (to be!) Here are the next steps in restoring an old boat.

#7 Create a conservative budget

Take your number and pad it by 30%. It is all too easy to let costs get out of hand. Do your homework. The more knowledge that goes into that budget, the less costs will surprise you. Front end work pays huge dividends.

#8 Come up with an educated guess at the timeline in total work hours

And then multiply it by 4 (If you know someone who does this work a lot, take their estimate and double it; they are faster than you)!

Then break it down into phases to make the overall project less daunting. Tracking your working time in hours keeps focus and doesn’t punish you for life getting in the way.

I made a game of it by tracking my active work-on-the-boat time in hours with an app called Toggl. If you’re at all competitive, this really pushes you to keep getting out there to beat your weekly and monthly bests. Celebrate the small victories; don’t punish the shortcomings.

#9 Build in expandability, especially in your electoral system (think battery space)

Make sure you have spare breakers on your panel and room in your conduits. Always install pull strings. No one in the 70s could have imagined the electrical needs of the modern boat, so don’t make the same mistake.

Future you will thank you.

If you’re reinstalling batteries then check out the best lithium marine batteries . Aim for a slightly bigger bank than you think you’ll need! ⚡ We highly recommend BattleBorn LiFePO4 batteries ⚡

#10 Experiment with clever ideas for maximizing your space

Keep what works. Tweak what needs adjusting. And scrap the flops. This is your opportunity to get creative. Test your original ideas.

Copy what others have done on their boats and modify what you find when researching tiny living and RV sources. Sometimes building a custom solution is the right way to go, but they often don’t work as expected.

If a production solution is available, it may cost slightly more but will save you more in time and headache.

As an example, we built our own propane alarm and on/off solenoid because the commercially available one seemed so expensive (and I thought it was ugly).

Finding all the components took hours and hours, and when I had collected them all, I’d only saved about 25%. Installing everything, and getting the sniffer, switches, and solenoid to all work together, was a huge headache. If I could do it all again, I’d just buy that ugly thing.

#11 Stick with it

The paradox of a major boat refit is that with little exception, every job sucks. Some suck a lot. You’ll have your head below your ass, sanding for hours, crammed in a tiny locker, but the satisfaction you’ll feel at the end of the day makes it all worthwhile.

Over the weeks and months of our old sailboat restoration, I experienced periods of high motivation where working on the boat was the only thing I wanted to do.

Things like eating, sleeping, and my day job just got in the way.

Other times, making myself get out there was like getting a 6-year-old to eat peas: damn near impossible. Motivational ebb and flow is a natural part of any long undertaking, but you have to push through it and keep going.

Don’t be another person selling a partially refitted boat. STICK WITH IT!

#12 Use perfection as the unachievable goal that it is

Instead, focus on safety and functionality. The goal is to get out there and enjoy your hard work, not worry away over every imperfection. You’re the only one that will notice anyway.

You’re never going to actually finish the boat refit; there will always be items on the to-do list. Once she’s fully functional and safe, go enjoy her. You can work on the never-ending list as you go.

Refitting Drifter was one of the single most rewarding undertakings I’ve ever done.

We live aboard, so every day I’m surrounded by the fruits of our labor. While there are flaws, the good far exceeds the bad. I know every system, and every nook and cranny. Get out there and find your opportunity. In the end, you’ll be so glad that you did!

Conclusion: Tips For Restoring an Old Boat

If you’re lucky enough to find an old boat that’s still in good shape, then you’re well on your way to having a great time out on the water. With just a little bit of elbow grease and know-how, you can have your boat sailing like new again.

Thanks for reading and we hope these tips helped!

Wondering what it’s like to live on a boat on land in a boatyard? Give this article a read to prepare you!

Chris and his wife Kelly bought their 1972 Nauticat 38 in April of 2017, and in May of 2019 went full steam ahead with an extensive refit in the driveway of their home in Portland OR.

They splashed and christened Drifter in the summer of 2022 and moved aboard full-time that September.

They are awaiting a weather window to tackle the wild west coast of the United States and begin cruising full-time starting with Mexico and Central America with the intent of continuing west.

Find their whole refit adventure documented along the way at YouTube.com/SailingAdrift. Feel free to contact them directly with any thoughts and questions through their website: www.SailingAdrift.com or by emailing [email protected]

Similar Posts

Is Sailing For The Rich?

Sailing Stories

11 Tips For Crossing The Atlantic By Sailboat 2024

Liveaboard Marinas: What’s It Like To Live In A Marina

The Best Lithium Marine Batteries For Your Boat 2024

How Much Does It Really Cost To Live On Board A Sailboat?

One comment.

Should be able to pay moorage before launching and make the rest of us look like vagrants with 3 kids

Comments are closed.

Sail Far Live Free

Tips for sailboat restoration.

Good Advice

I just bought a 1973 Pearson 30. The Atomic 4 is shot and needs to be removed, I know very little about engines. Any ideas on what I should do would be helpful. I understand that the A4 developed about 30hp and I'm thinking a 16hp diesel would probably suit my needs(I sail on a 43,000 acre lake). Any thoughts?

16 HP sounds about right. The atomic 4 usually has a small propeller and higher RPM than diesels, so check the max diameter prop you can fit with 10-15% of clearance top and bottom. You may want less of a reduction gear. Also consider engine and fuel weight. "The propeller handbook" by Dave Gerr is a good resource. Most older boats have small props that can't make use of higher HP.

Post a Comment

Popular posts from this blog, top 10 favorite affordable bluewater sailboats, go small and go now 5 pocket cruisers to take you anywhere.

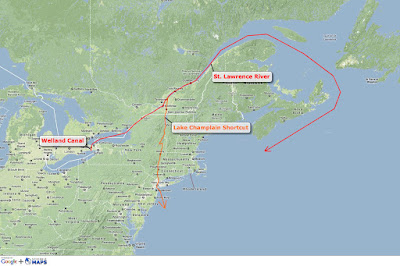

Escape to the Sea: How to get from the Great Lakes to the Caribbean

DIY Boat Restoration: Tips and Tricks for a Budget-Friendly Makeover

Restoring an old boat can be a rewarding and cost-effective way to breathe new life into a beloved vessel.

While it may seem like a daunting task, with the right tips and tricks, you can embark on a DIY boat restoration project that’s easier on your wallet and more satisfying than you might expect.

Helpful Boat Restoration Guides

1. set clear goals, 2. create a detailed plan, 3. prioritize safety, 4. do your own research, 5. salvage and recycle, 6. budget-friendly materials, 7. diy fiberglass repairs, 8. refinishing and painting, 9. upholstery on a budget, 10. routine maintenance.

Boat Restoration Guide

Fiberglass Boat Restoration Guide

Metal Shape Welding Instructions For Boat Building

10 Tips To Make Boat Restoration Simple

In this guide, we’ll share valuable insights and cost-saving strategies to help you navigate your boat restoration journey with confidence.

Before you dive into your boat restoration, determine the scope of your project.

Are you looking for a complete overhaul or just some minor repairs and cosmetic touch-ups?

Setting clear goals will help you avoid overspending and stay focused on your budget.

A well-thought-out plan is essential. Take the time to assess the boat’s condition and identify areas that require attention.

Create a checklist of tasks, including materials and tools needed.

A comprehensive plan will prevent impulse purchases and keep you on track.

Safety should always be a top priority.

Inspect the boat for structural issues, such as rot or damage, and address them first.

This ensures that your boat is safe for use, and you won’t compromise your safety while on the water.

Become a savvy researcher. Look for DIY boat restoration resources, such as books, online forums, and video tutorials.

Learning from others’ experiences can save you from common pitfalls and provide valuable insights.

When possible, salvage and recycle materials from your boat. Old hardware, wood, and even upholstery can often be refurbished or repurposed.

This not only saves money but also adds character to your project.

Shopping for materials doesn’t have to break the bank.

Consider marine-grade plywood alternatives, explore second-hand stores for décor, and compare prices from different suppliers to find the best deals.

Don’t forget to inquire about discounts or bulk rates.

Many small fiberglass repairs can be done at home.

Learning basic fiberglass repair techniques will save you money on hiring professionals.

Invest in a fiberglass repair kit and follow instructional videos to tackle small cracks or holes.

For cosmetic improvements, you can save money by refinishing and painting your boat yourself.

Proper sanding, priming, and using quality marine paint can make your boat look as good as new. Don’t forget to choose colors that won’t fade quickly under the sun.

Reupholstering your boat’s seats and cushions can be expensive. Consider buying discounted marine-grade vinyl and learning basic sewing skills to make your own seat covers.

Alternatively, look for deals on pre-made seat covers.

After your boat is restored, keep it in top condition by following a regular maintenance schedule.

Routine care will extend the life of your boat and prevent costly repairs in the future.

Embarking on a DIY boat restoration project can be both a labor of love and an excellent way to save money.

By setting clear goals, creating a detailed plan, and implementing these tips and tricks, you can transform your old boat into a source of pride without breaking the bank.

Remember that patience and perseverance are key to a successful boat restoration, and the satisfaction of sailing in a vessel you’ve restored with your own hands is truly priceless.

You may also be interested in reading our guide that shows you how to build a flat bottom boat and also our boat building plans .

Mick McGrath

Recent Content

518 Illustrated Boat Plans

518 boat plans for less than the price of your lunch! MyBoatPlans Reviews MyBoatPlans is a comprehensive collection of 518 boat plans, 40 videos and about 500 pages of boat building guides. I've...

Set Sail with Confidence: Essential Boat Safety Tips for All Ages and Furry Friends

Picture yourself gliding over crystal-clear waters, the wind in your hair, and the sun kissing your skin. The open sea offers endless possibilities for adventure, but before you hoist the sails, it's...

YACHT RESTORATION PROJECTS

If you've ever dreamed of updating or restoring an older boat like a car enthusiast revives a classic '71 Thunderbird, the Yachting Solutions team will follow your lead and bring that vision into reality. Using our resto-mod process, we refurbish the classic lines of vintage vessels while incorporating modern performance features, all to deliver a customized watercraft that speaks to your soul.

A hybrid of restoration and modification, Yachting Solution's resto-mod process preserves your boat's timeless look with modern upgrades to meet today's performance needs. From small lake boats to large motor yachts, we're passionate about the art of boat restoration. We'll work closely with you to create a personalized resto-mod concept and deliver a fully realized remodel you can take pride in.

Whether you want to restore a 60s Boston Whaler, refresh your boat's exterior paint, refurbish your yacht's interior, or get a quick installation of the latest boat mods, give Yachting Solutions a call. Our expert shipwrights, painters, varnishers, and technicians are here to help return your watercraft to its former glory and provide cutting-edge upgrades to enhance all your boating adventures.

1971 TRUMPY

2013 INTREPID

1963 BERTRAM

1954 HUCKINS

1964 WHITICAR

1956 HUCKINS

1930 HUCKINS

1940 CHRIS-CRAFT

1989 BOSTON WHALER

1972 AURELIA CLASSIC

COW TOW LOBSTER

You have quite a dream team there. I prefer to be known not as a complainer, but as one of the few customers that will actually follow through and let you know how pleased we were with all the service your folks have given us. They seem to complement each other and your business perfectly. Many Thanks for all they do and have done for us!

The experience of evaluating, test driving and buying a boat from these guys was fun and outstanding, not to beat the experience of taking delivery and their knowledge, service and customer care. Thank you Yachting Solutions!

Paul Schuepp