FREE!ship designs on the WebDiy boat designs by famous designers. | Designer | No. | Design | Description | Image | FREE!ship File | Length | Beam | Draft | | | 215 | Thomaston Galley | Dayboat. Row, sail, and motor.

Ref: SB Ch#8

Plans available from | |

by Bruce Hallman | 15'6"

4.70 m | 4'1"

1.25 m | | | | 372 | Romp | Ocean cruising yawl, centerboard, cold-molded.

Ref: MAIB V#16 No13

Plans available from | |

by Bruce Hallman | 30'

9.15 m | 8'4"

2.55 m | | | | 376 | Mikim /

Ilex | Fishing Launch - carvel hull.

Ref: 30oddBoats Ch#19, SBJ V#1 No4

Plans available from | |

by Bruce Hallman | 24'

7.30 m | 7'10"

2.40 m | | | | 381 | Windsprint | Daysailer

Plans available from

or | |

by Mark Albanese | 16'

4.90 m | 4'6"

1.40 m | 4"

0.10 m | | | 391 | Fiddler II | Minimal Cruiser - planing hull, OB

Ref: 30oddBoats Ch#4

Plans available from | |

by Bruce Hallman | 15'10"

4.80 m | 6'8"

2.00 m | 6"

0.15 m | | | 458 | Brick | "The" Boat, max. capacity for 3 sheets. Sail, row, small OB.

Ref: BWOAM Ch#2, MAIB #15 No23

Plans available from | |

by Stefan Probst | 8'

2.45 m | 4'

1.20 m | 6"

0.15 m

@460 lbs

210 kg | | | 464 | Willow | Leeboard Sloop

Ref: MAIB V#9 No12

Plans available from | |

by Bruce Hallman | 30'

9.15 m | 8'6"

2.60 m | | | | 471 | Summer Ease | Hard-chine water-ballasted cat-ketch

Ref: MAIB V#16 No22

Plans available from | |

by Bruce Hallman | 23'6"

7.15 m | | | | | 484 | Anhinga | Big sailing canoe + oars

Ref: MAIB V#6 No11

Plans available from | |

by Mark Albanese | 23'3"

7.10 m | 5'

1.50 m | 6"

0.15 m | | | 488 | Open Water Utility | Big rough water capable speedboat

Plans available from | |

by Bruce Hallman | 25'6"

7.75 m | 7'6"

2.30 m | 1'10"

0.55 m

| | | 528? | Missouri River Keelboat | Ref: MAIB V#9 No11

Plans available from | |

by Bruce Hallman | 38'9"

11.80 m | 8'

2.45 m | | | | 556 | Idaho | Wheelchair accessible plywood flat-bottomed OB cruiser

Plans available from | |

by Stefan Probst | 31'

9.45 m | 5'3"

1.60 m | 6"

0.15 m | | | 566 | Commuter | Ref: MAIB V#11 No2

Plans available from | |

by Bruce Hallman | 20'

6.10 m | 7'9"

2.35 m | 15"?

0.38 m | | | 578 | Unpretentious Cabin Cruiser | Ref: MAIB V#9 No10

Plans available from | |

by Bruce Hallman | 33'

10.05 m | 10'

3.05 m | | | | 583 | Power Yawlboat | Workboat style

Ref: MAIB V#9 No15

Plans available from | |

by Bruce Hallman | 11'4"

3.45 m | 5'3"

1.60 m | 4"?

0.10 m | | | 585 | Hermes 21 | Long Distance Rowing Cruiser

Ref: MAIB V#17 No23

Plans available from | |

by Bruce Hallman | 20'

6.10 m | 5'

1.50 m | | | | 648 | Shivaree 18 /

Lobster Skiff | Molded or lapstrake center console OB.

Ref: BDQ#18

Plans available from | |

by Bruce Hallman | 18'

5.50 m | 7'

2.15 m | 1'1"

0.33 m | | | 653 | Tahiti | Diesel Inboard,

Ocean Passagemaker

Ref: MAIB V#17 No12-14

Plans available from | |

by Bruce Hallman | 38'6"

11.75 m | 9'6"

2.90 m | 1'10"

0.55 m | | | 662 | Fiji | A 39' go-anywhere yawl.

Ref: MAIB V#20 No10-12,17, BDQ#22

Plans available from | |

by Bruce Hallman | 39'5"

12.00 m | 11'10"

3.60 m | 2'1"

0.65 m | (C5) | Cartoon 5:

Outboard-Powered

Canal Cruiser | For one or two small outboards

on very protected waters only

Ref: SBJ Cartoon #5

(Cartoon only, no plans available) | |

by Stefan Probst | 25'6"

7.75 m | 6'9"

2.05 m | 0'8"

0.20 m | | | (C40) | Cartoon 40 | Casual daysailer/racer.

Ref: SBJ #64, Cartoon #40

No complete Plans,

but drawings available from | |

by Stefan Probst

by Bruce Hallman | 15'6"

4.70 m | 6'5"

1.95 m | 0'11"

0.92 m | n/a | Inlet Runner | Plywood (or other sheet) rough water utility.

Ref: MAIB V14 #10

(Cartoon only, no plans available) | |

by Bruce Hallman | 22'

6.70 m | 8'5"

2.55 m | | | | n/a | One Man Liveaboard Concept | Ref: MAIB V16 #3

(Concept study only, no plans available) | |

by Bruce Hallman | 19'

5.80 m | 7'6"

2.30 m | | | | n/a | Mobile Houseboat Concept /

Puffer | Ref: MAIB V16 #15

(Concept study only, no plans available) | |

by Bruce Hallman | 40'

12.20 m | 14'

4.25 m | 2'

0.60 m | ??? | Diablo Grande | Double chine open powerboat for 40hp OB.

Ref: BDQ#18

Plans available from

or | |

by Bruce Hallman | 18'

5.50 m | 6'3"

1.90 m | | ??? | Supermouse | Microcruiser - lapstrake pram

Ref: BWAOM Ch#9

Plans available from | |

by Bruce Hallman | 11'6"

3.50 m | 6'6"

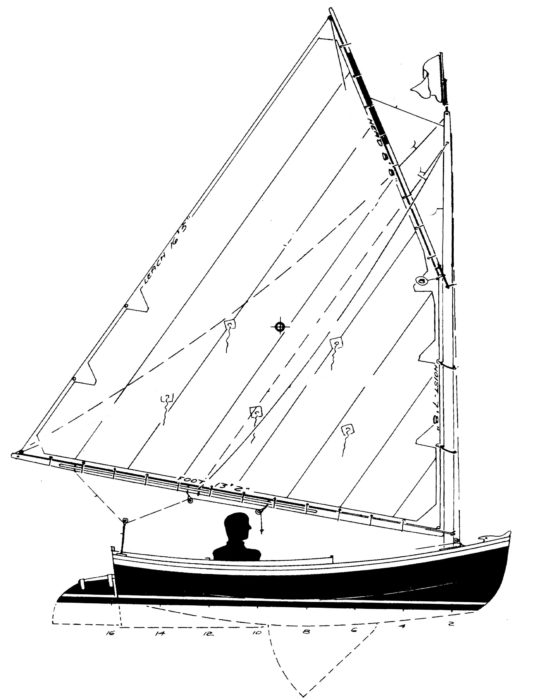

2.00 m | | | | ??? | Lapstrake Chebacco | Dayboat - lapstrake cat yawl

Ref: BWAOM Ch#45

Plans available from | |

by Bruce Hallman | 19'6"

5.95 m | 7'9"

2.35 m | 3'11"

1.20 m

| | | | Dockbox | Mini/Nano Shanty

6 sheets

Plans available from | |

by Stefan Probst | 8'

2.45 m | 5'6"

1.65 m | 4"

0.10 m | | Jim Michalak | | Piccup Squared | A "squared" version of the Piccup Pram

4 sheets

Plans available from | |

by Stefan Probst | 11'

3.35 m | 4'6"

1.35 m | 5"

0.15 m

@415 pounds | Boat Profile Bolger's adaptation of the Beetle Cat for tack-and-tape construction From Issue Small Boats Annual 2022 September 2021 I built a Bolger Bobcat back in 1998 and, while I very much enjoyed building and sailing it, three years later I sold it as I turned my attention to another boat. I soon came to regret selling my catboat. This past winter, with space in the shop and no project to tide me over, I decided to build another one and purchased Harold “Dynamite” Payson’s Build the Instant Catboat . This 42-page building manual notes that the 12′ Bobcat was designed in 1985 by Philip Bolger for H.H. Payson and Co. as a hard-chined, tack-and-tape plywood adaptation of the carvel-planked Beetle Cat designed in 1921 by John Beetle of New Bedford, Massachusetts. In his book, Payson lays out the project in great detail and with frequent humor. He includes multiple detailed drawings, photos, and step-by-step instructions, including rigging the sail and what type of line to use for the halyards. The hull panels and permanent bulkheads are drawn out on sheets of 1/4″ plywood; all of the parts can be made with 10 sheets, including the deck panels, centerboard trunk, centerboard, and bulkheads. Payson recommends marine-grade or AC exterior plywood; I went with fir AC. The plywood I got was excellent quality, and I had no problems bending the panels into the shapes they needed to be. The manual provides measured drawings for the hull planking—there is no need for spiling the shapes from the building form—and goes into great detail on drawing and cutting out the pieces.  Assembly of the hull begins with the sides bent around the transom and two of the five bulkheads. There are five bulkheads—designated A, B, C, D, and E from bow to stern—that serve as molds but are also permanent fixtures in the boat. Instead of setting all five up on a ladder frame, just bulkheads B and E and the transom are set up and around them the side panels bent by drawing their forward ends together. The rest of the bulkheads and the stem are then attached inside the side panels without requiring a ladder frame or strongback to support them. The bottom panel follows and is attached to the bulkheads. Attaching the bilge panels is the most difficult part of the hull construction due to their size, the compound curve at bulkhead A, and the twist to attach them to the stem. I applied towels soaked in hot water to the forward ends and was able to coax them into place without too much effort. Payson gives a good description and photos of the process and how he overcame the minor difficulty he had.  The forward ends on the bilge panels get “tortured” into a compound curve by gentle arcs on the edges of the forwardmost frame. As the bottom and bilge panels are added, they are temporarily screwed to temporary cleats on the bulkheads, until the seams are secured with fiberglass tape and epoxy, first on the outside and then on the inside after the hull is turned over and the inside joints are taped. This completes the basic hull. The solid stock the plans require for the rubrails, deckbeams, skeg, and floorboards is 1×2 or 1×4 lumber. I was able to repurpose a pine 2×10 and leftover lumber, resawn to the dimensions I needed. I laminated the tiller from two layers of maple. Payson recommends flotation in the bow and under the decks aft. Before installing the deck, I fit 2″-thick insulation foam between the deckbeams and filled the section between the forward bulkhead and stem with it. The hull’s exterior and deck are covered in fiberglass set in epoxy.  Only the aft half of the centerboard trunk intrudes into the cockpit. The forward half is under the foredeck. T he plans call for a coaming made of 1/2″ plywood, installed in three sections joined with square corners. Bolger said of the coaming: “I haven’t duplicated the curved cockpit coaming of the Beetle Cat. I like the looks of it but it doesn’t seem to suit the style of the plywood boat as well, and there’s no functional advantage. It’s an economy in a shop with a steambox going all the time and a steady supply of fresh-cut oak coming in, but not so in a plywood-and-glue operation.” I thought that Bolger’s coaming looked too boxy, and laminated mine from three layers of 1/8″ mahogany plywood in one continuous piece with rounded corners. It was the only significant modification I made to the design. The mast is 15′, the boom 13′6″, and the gaff 8′. The mast is built from two 3-1/2″ planks with 1/2″ spacers between them and tapers to 2-1/2″ the top 6′. The centers of the planks have a 1/2″-deep-by-1-1/2″-wide groove cut in them to make the mast hollow and save weight. I made several cuts with a circular saw and chiseled out the waste.  A lead weight in the centerboard pulls it down, and a peg in one of three holes holds it position for partial deployment. The toggle, on the end of an 8″ lanyard, is the final limiter. The curved coaming here is a departure from the square corners in the plans. The Bobcat’s centerboard is made of three layers of 1/4″ plywood with a 6″ square cut out for weight—10.9 lbs of poured-in lead, according to the plans. In lieu of working with molten lead and its toxic fumes, I used lead shot, leftover from my reloading days, mixed with epoxy. The board, finished with a coat of epoxy, turned out well.  The barn-door rudder allows the cat to sail shallows and come ashore without being removed. Its horizontal bottom plate, seen here submerged, gives it a solid purchase when the boat is heeled. The barn-door rudder is 24″ long, 16″ tall, and 1-1/2″ thick. I made mine of three layers of 1/2″ ply. Its bottom edge is even with that of the skeg and has a bottom plate that is 12″ wide and 23-1/2″ long. “Cats with shallow rudders,” wrote Bolger, “have a bad name for weathercocking against a hard-over rudder when they’re overpowered, but since I learned to put end plates across the bottoms of the rudders I haven’t had any complaints about this. It’s astonishing how shallow a rudder can be and still steer the boat, if the water is kept from rushing off the bottom of the blade.” Payson notes in his book that he hadn’t heard of this “horizontal foot” before seeing it in Bolger’s plans, but he was quick to approve of it: “I can vouch for its effectiveness on Bobcat, for her rudder holds right on when she heels over.” The plans call for a pair of brass or stainless straps on top of the rudder so the tiller can be quickly inserted through the transom and held to the rudder blade. Lacking a means to bend the metal neatly, I opted to bolt the tiller to the rudder. I have access to a lake a short walk from my home so I have not trailered this boat, but its light weight—I figure 250 lbs—shouldn’t be a problem for any automobile. I can easily step the mast standing on the foredeck while the boat is afloat, and in about 20 minutes from start to finish I’ll have the boom, gaff, and halyards for the throat, peak, and topping lift in place. There is ample room in the cockpit for moving around, shifting weight, tending lines, etc. Standing to raise or lower the sail is no problem due to the stability provided by the wide beam. The aft seat is large, but most of the time I sit on the floor or on the side deck. I built a pair of removable seats that slip over the coaming to make a more comfortable perch than the coaming’s edge. The low position of the boom blocks visibility to leeward, unless I’m sitting on the floorboards. There is a large area under the foredeck for storage with easy access.  The Bobcat carries a 110 sq ft gaff sail. The two lines emerging from the masthead are the peak halyard and the topping lift. I am very pleased with the Bobcat’s performance. For a 12-footer, it feels more like a big boat. The wide beam makes for a stable platform, and it is an excellent boat for a first-time sailor. It is surprisingly quick to windward. “A gaff sail like this can be cut as close-winded as a jib-headed sail,” according to Bolger. In my estimation, the catboat will tack as close as 30 degrees to windward. Coming about, it carries enough way to avoid getting caught in irons. It doesn’t seem to mind gusts; it just heels over only so far and stops, even when hit with a wind from a different direction, as happens in the lake I sail in. Typical of catboats, the Bobcat has a bit of weather helm which helps the cat round up in gusts. In a jibe, the gaff follows right along with the boom without any problem. Accommodations for rowing—a seat and oarlocks—are not included in the plans, and rowing with a conveniently sized pair of oars is not possible due to the 6′ beam. I use a canoe paddle for auxiliary power; it is easy to store under the foredeck when sailing. I am considering integrating a small electric trolling motor alongside the skeg for auxiliary power. The boat’s light weight should make it easily driven. I have a little over $2,000 invested in the boat, including the sail, which was the largest single expense and ordered from H.H. Payson Co. Their sailmaker has a five-month backlog, but I was advised that sometimes they find time for a quicker delivery to Payson’s customers.  Bobcat Particulars [table] Length/12′ 3″ Beam/6′ Sail area/110 sq ft Weight/ approx. 250 lbs Draft, board up /11″  Plans ($45) and full-sized patterns ($105) for the Bobcat are available from H.H. Payson & Company. The boat goes by three different names: Bobcat, Tiny Cat, and the Instant Catboat. Small-scale plans and building instructions for Bobcat are included in Build the Instant CatBoat , by Dynamite Payson, available from H.H. Payson & Company and The WoodenBoat Store . The book’s small-scale plans were intended as illustrations only, not for reading text and numbers; the plans and patterns from H.H. Payson & Company are recommended for building the Bobcat. Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Magazine readers would enjoy? Please email us! Share this article Join The ConversationWe welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link. Comments (18)I built the Bobcat back in 2004/5. Got the plans and full sized patterns from Payton. It was an easy build and much fun sailing. I was initially skeptical of the rudder design but it proved to be excellent. Built a motor mount on the transom for a 2-hp Yamaha. I’m wanting a motor mount for my Bobcat but haven’t found a suitable mount. Could you provide any details on how you attached it to the transom? I built a Bobcat and can vouch for what’s reported here; it’s an excellent boat and build. Surprisingly close-winded, but 30 degrees? No. The stern seat’s useless; in my boat it serves only to hold an Opti flotation bag in place. I saved a ton of time and money by using the spars and sail from a wrecked Beetle Cat — identical above-deck dimensions except for the roach in the Beetle sail; requires minor fiddling with the step. Works fine. No one has mentioned the planking. Is it scarfed or using butt blocks to get the length needed ? Great looking little sailor ! Regards David Jackson David, Butt blocks are used. Hi John, What is the other boat in the pic of your workshop ? Regards David Jackson David, It is my steam launch, E. SCOTT HAMMOND. There was an editorial about it in the October 2018 issue of Small Boats. I miss my Bobcat! Here’s a little video I made sailing her last winter. What a great video!! Thanks for sharing it. Thank you! Your piece was a great read! I am envious of your nearby lake. I buy and sell a lot of boats in need. The Bobcat is one I would definitely own again. An observation about bending plywood panels: It is a time-honored practice to use hot water and towels for bending plywood, but in fact, the water adds nothing to the process (except to distribute the heat). The problem with this, besides the inevitable messiness, is that it also raises the grain, and means the wood has to dry out before moving on to other procedures. Fir plywood is especially problematic with grain raising. Instead, I like to use dry heat for bending (and it works on solid wood as well as plywood). For a panel the size of Bobcat’s bilge plank, I’d use a well spread out, broad source of heat, such as an electric infra red space heater, the kind with a parabolic reflector. It only takes a few minutes’, especially with plywood as thin as 1/4″, to heat it sufficiently. You can check with a bare hand to tell if it seems hot enough. Apply bending pressure every so often, until you can feel the panel relax and start to bend. After withdrawing the heat, the wood stiffens up very quickly, and will hold its bent shape. If it still seems stubborn, it’s easy enough to reapply the heat for another try. For smaller pieces, a heat gun works well. Be careful not to scorch the wood. David, I built a Bobcat in the winter of 1999/2000. In a barely heated detached double garage in MN. I don’t recall any big problems bending the plywood. I’d previously built a Simmons Sea-Skiff and after bending the forward end of keelson at on that … The Bobcat was my first stitch and glue and I was more worried about how that would go, so I may have spaced bending problems. An aside: My wife and I happened to be in Maine in 1999 and stopped in to say hello to Harold Payton. We chatted for a short time with Harold and his wife in his shop. I may have bought plans for the Bobcat that day. Later that day or the next I went to Bohndell Sails in Rockport and ordered a sail for the Bobcat. I’ve always admired this design and have Payson’s book. That curved coaming is such a nice feature and it, along with your article, has renewed my interest building one for myself My father and a group of his age or there abouts finished a bunch of cold-molded hulls, I believe purchased surplus right after WW II. The hulls were found some where in Delaware or Maryland by a friend. They ended up as sailing dinghies, 9′ long, mast about 18′, with 65 sq ft sail area, called Bobcats. They were centerboarders. They were a lot of fun for us as kids growing up with all kinds of racing and special events, i.e. scavenger hunts, pajama races, picnics, etc. Also frost-biting in the winter. This was at the yacht club in Sea Cliff, Long Island, New York, off western Long Island Sound. In the early ’50s they started another building program for Penguins. I’m finishing a half-built Bobcat I dragged home from up north. I have a few sails in the Beetle Cat and so I deleted the rear seat for more lounge room. Can’t wait to hit the local waters next year. Have a Sailrite kit just waiting for those winter doldrums. Thanks so much for the article and photos. John, Nice article! Has anyone thought of starting a Bobcat Owners Association? It would be nice to share information about details of the build, trailering, adventures and observations. This is my next build and more photos of the building process are always welcome. I finished building a Bobcat from a half-built hull and converted a salvaged Beetle Cat rig for it, which works splendidly well. I do wish Phil Bolger hadn’t specified that wide seat-like object in the stern. You can sit there, but you shouldn’t; it throws the trim off and makes the boat look awkward. Check out the first photo in this article: the boat’s squatting with the bow out of the water. Look at where Bolger places the sailor in his profile drawing: forward of that horrid back bench. I put side benches in, which cramps the cockpit somewhat, but the boat sails like a dream with the better trim. Andrew, I agree the aft seat is awkward and I had thought about the side benches you mentioned. I usually end up sitting on the side deck and made seats that fit over the coaming. Leave a Reply Cancel replyYour email address will not be published. Required fields are marked * Stay On Course More From This Issue The Rhodes 19Facing rising materials costs and a poor economy, O’Day had discontinued production of the Rhodes 19 by 1980. That could have been the end of the class, but its officers…  The plans for the Ellen from Brooks Boat Designs are on 12 sheets and include full-sized patterns for the molds, transom, rudder, and other parts. No lofting is required. The…  The barn-door rudder is 24″ long, 16″ tall, and 1-1/2″ thick. I made mine of three layers of 1/2″ ply. Its bottom edge is even with that of the skeg…  Sponge Docks Skiff 13When I happened across the Sponge Docks Skiff 13 by Bedard Yacht Design, I was immediately intrigued by the simple, practical interior and the gently curving sheer and transom sides.…  I have been impressed by the solid feel and stability of Penny Fee. Lightly loaded, the transom is well clear of the water, promising good load-carrying capabilities without added drag.…  rance’s rugged Atlantic coastline is a popular and challenging cruising ground, but it was not so long ago that countless fleets of small workboats called its remote harbors and rocky...  Expedition Rowboat from Angusfter 20 years spent building, then sailing our beloved 38′ ketch, a Herreshoff Nereia, on the Great Lakes and St. Lawrence River, there came a point when Louise and I...  In light winds, you might normally sit well forward while going upwind, but with the Goose, the square bow needs to be out of the water or you will be…  The JiffyV-22 is 22′ 6″ long, has a beam of 8′ 6″, and draws just under 2′. With its cabin, it is reminiscent of classic Maine lobsterboats, and is designed…  Conrad Natzio originally designed the 14′ Sandpiper for a workshop and demonstration at the Boat ’99 show in the United Kingdom. The first four of these attractive little sailing and…  Boat Trailering TipsTo deal with breakdowns on our long-range trips, we carry a grease gun, rags, either a spare set of grease-packed bearings or a hub with bearings already installed, along with…  Reader Built Boats He started with a wedge shape for the hull: a plumb stem to part waves and a flat run for planing. As he explored the shape with a model of…  Surf CrabskiffThe hull is designed for simplified chine-log construction, which eliminates the necessity for a strongback or jig. All the plywood parts except the rudder fit onto just four 4′ x…  The boat handles beautifully in most anything I’m comfortable taking on in an 18’ boat. It turns exceptionally well when I’m cruising winding rivers, and on hard turns at speed…   Down East WorkboatGardner drew the design in 1981, basing it on old photographs and measurements of an 18′ workboat from Washington County, Maine. He described the design as a double wedge, the…  The Crawford Melonseed SkiffThe cockpit is a little over 6′ long—big enough for two people and a picnic. There’s room up under the deck for a cooler, anchor, and other gear, and a…  Designed to be light, the Savo 650D’s keelson, gunwales, and frames are made of pine or spruce. The fully equipped boat weighs in at just over 100 lbs. The length…  The Wittholz CatboatThe plans for the 17′ 1″ plywood catboat include 11 sheets with good construction detail: materials, dimensions, fastening schedules, notes, and comments. Several alternatives are included: self-bailer instead of deep…  Don’t Tell Me I Can’t“A little too big” came back to me as I stood in a lumberyard collecting the first of the materials for building a Greenland skin-on-frame kayak, but the echoes of…  Elfyn sails very well without the daggerboard, even tacking into the wind. When returning to our launch ramp against a light headwind, I raised the daggerboard and Elfyn kept on…  In a word, my overall impression of the boat’s performance under way was: “Easy.” With 300 lbs of crew (my daughter and myself) and 200 lbs of foam-wrapped lead ballast…  Dan has been drawing, painting, and sculpting for the better part of his life and has an artist’s eye. He recalls, “I got to thinking that wood could be an…  Built by the BookThe lockdown in New Zealand began on March 23 and David stayed home to do his part in slowing the spread of COVID-19. He focused on his canoe projects and…  A Kid-Built CurraghIn 2019, Ric took on a more ambitious project, a currach, with his fourth and fifth graders. The frame of their version of the traditional Irish rowing boat, built without… More Boat Profile Black SkimmerThe 25'3" Black Skimmer floats in 10" of water and sails handily in not much more. She stays with, or ahead of, most stock boats of comparable size on all…  The Tolman SkiffRenn Tolman designed his eponymous skiff as a workhorse for rugged Alaskan environs. The boat has proven to be adaptable to a wide range of locales—and to a wide range…  Sand DollarI do not have a lot of experience sailing other boats, but the Sand Dollar is quite responsive. When the wind gusts just a little, the boat heels immediately and…  I contacted François Vivier in the fall of 2016 to inquire if his Morbic 12, designed for lapstrake plywood, could be built with strip planks. He replied, “Yes, with some… Subscribe Today!Become a subscriber today and you’ll recieve a new issue every month plus unlimited access to our full archive of backlogged issues. Already a subscriber? Sign In Subscribe For Full AccessFlipbooks are available to paid subscribers only. Subscribe now or log in for access.  |

IMAGES

VIDEO

COMMENTS

The Bolger Boats Plans List. A-E. F-K. L-P. Q-U. V-Z. Philip C Bolger passed away in May 2009 after providing the world with many delightful plans. Plans contact: Susanne Altenburger.

As some of you might already be aware, (and for those who are not), I have been working on a web page that collects together a master listing of all known Phil Bolger boat designs. To my knowledge, no one else has done something like this.

DIY Boat Designs by Famous Designers. Note: those files are for study, illustration, fun, ... but not to build a boat! Special thanks to Bruce Hallman for his permission to link to his files, and for some images! Photos to illustrate the designs are taken from where I could find them on the Net.

Re: Master listing of all known Phil Bolger designs. The pipe berths work fine. When Phil first saw them in my boat, he commented that they were the first he had seen installed on one of his designs. Most people disregarded them in his plans.

The book includes plans for Gypsy (15' sail/oar/outboard), Nymph (7'9" dinghy with sail option), Diablo (15' motor boat for up to 25 HP outboard) as well as 8 more "traditional instant boats" using the chine log method: 16' Lug-rigger Windsprint, 6'5" Tortoise, 8' Skimmer, Dynamite Sailboard, 16'June Bug, Madeline a 19'6" Pedal-driven ...

The boat goes by three different names: Bobcat, Tiny Cat, and the Instant Catboat. Small-scale plans and building instructions for Bobcat are included in Build the Instant CatBoat, by Dynamite Payson, available from H.H. Payson & Company and The WoodenBoat Store.